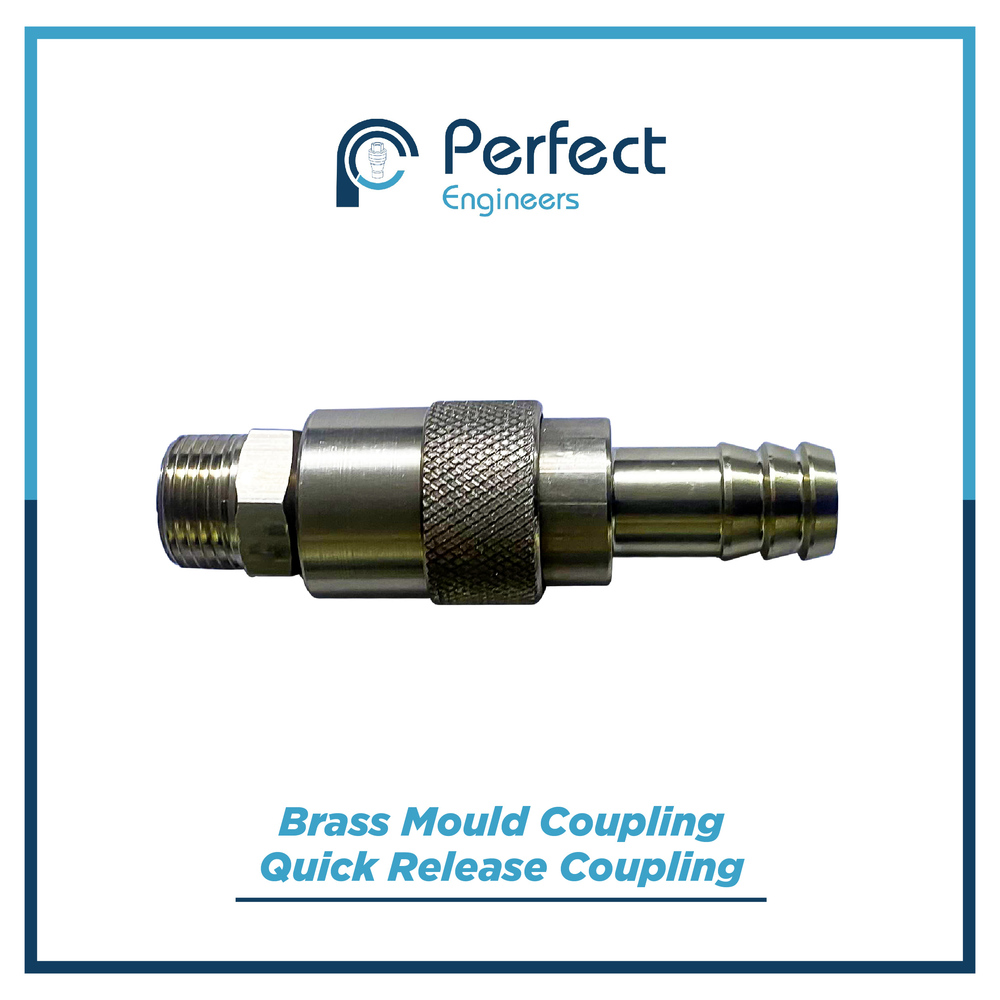

Moulding Quick Release Coupling

Product Details:

- Size 1/8 inch to 3/4 inch

- Product Type Moulding Quick Release Coupling

- Usage Industries

- Color stainless steel

- Thread NPT, METRIC, UNF, BSPT, BSPP, JIC

- Connection Other

- Head Code Round

- Click to View more

Moulding Quick Release Coupling Price And Quantity

- 500 Unit

- 230 INR/Unit

Moulding Quick Release Coupling Product Specifications

- Moulding Quick Release Coupling

- Industries

- Other

- 1/8 inch to 3/4 inch

- stainless steel

- NPT, METRIC, UNF, BSPT, BSPP, JIC

- Stainless Steel

- Forged

- Other

- Piping systems Pneumatics

- Round

Moulding Quick Release Coupling Trade Information

- Cash Advance (CA) Cash in Advance (CID) Cheque

- 1000 Unit Per Week

- 1 Week

- Standard, As per requirement,

- All India

- ISO 9001-2015

Product Description

ïQuick Release Couplings (QRCs) are essential components in injection molding processes, facilitating rapid and secure connections for coolant lines between molds and injection molding machines. They enable efficient temperature control during molding, which is crucial for product quality and cycle time reduction.ï

Key Features of Molding Quick Release Couplings:

-

High Flow Capacity: Designed to allow substantial coolant flow, ensuring effective temperature regulation of molds during the injection process.ï

-

Compact Design: Their small dimensions are tailored to fit the confined spaces within injection molds, where channels are deeply set and densely arranged.ï

-

Material Compatibility: Typically constructed from brass with Viton seals, these couplings offer resistance to high temperatures (up to 200C) and various chemicals, ensuring durability and reliability.ï

-

Pressure Resistance: Capable of withstanding working pressures up to and exceeding ten bar, suitable for the demanding conditions of injection molding.ï

Applications:

Molding quick release couplings are predominantly used to connect cooling or heating lines of molds with hoses supplying cooling water or heating agents. During the injection process, molten plastic is injected into the mold, which must maintain appropriate temperatures throughout its structure. After injection, the mold is cooled to facilitate the removal of the product. This temperature management process, known as thermostating, is efficiently supported by the use of quick release couplings.

FAQs of Moulding Quick Release Coupling:

Q: What are the available thread options for the Moulding Quick Release Coupling?

A: The available thread options for the Moulding Quick Release Coupling are NPT, METRIC, UNF, BSPT, BSPP, and JIC.Q: What applications are suitable for the Moulding Quick Release Coupling?

A: The Moulding Quick Release Coupling is suitable for piping systems and pneumatics applications in industries.Q: What sizes are offered for the Moulding Quick Release Coupling?

A: The Moulding Quick Release Coupling is available in sizes ranging from 1/8 inch to 3/4 inch.Q: What is the technique used in manufacturing the Moulding Quick Release Coupling?

A: The Moulding Quick Release Coupling is manufactured using the forged technique.Q: What material is the Moulding Quick Release Coupling made of?

A: The Moulding Quick Release Coupling is made of stainless steel.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Mould Type Quick Release Coupling' category

|

PERFECT ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese