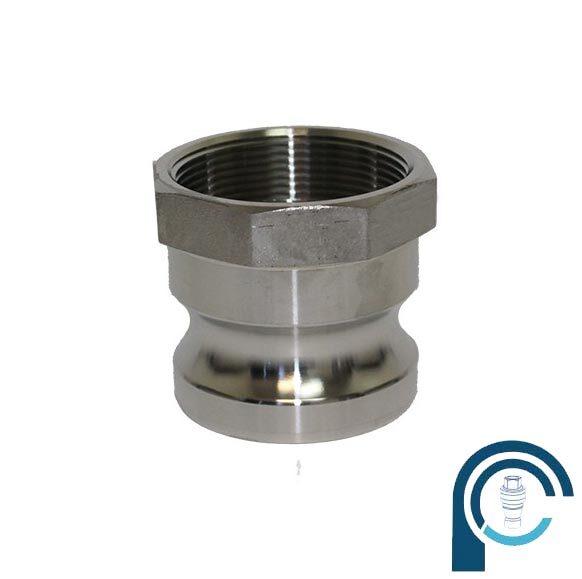

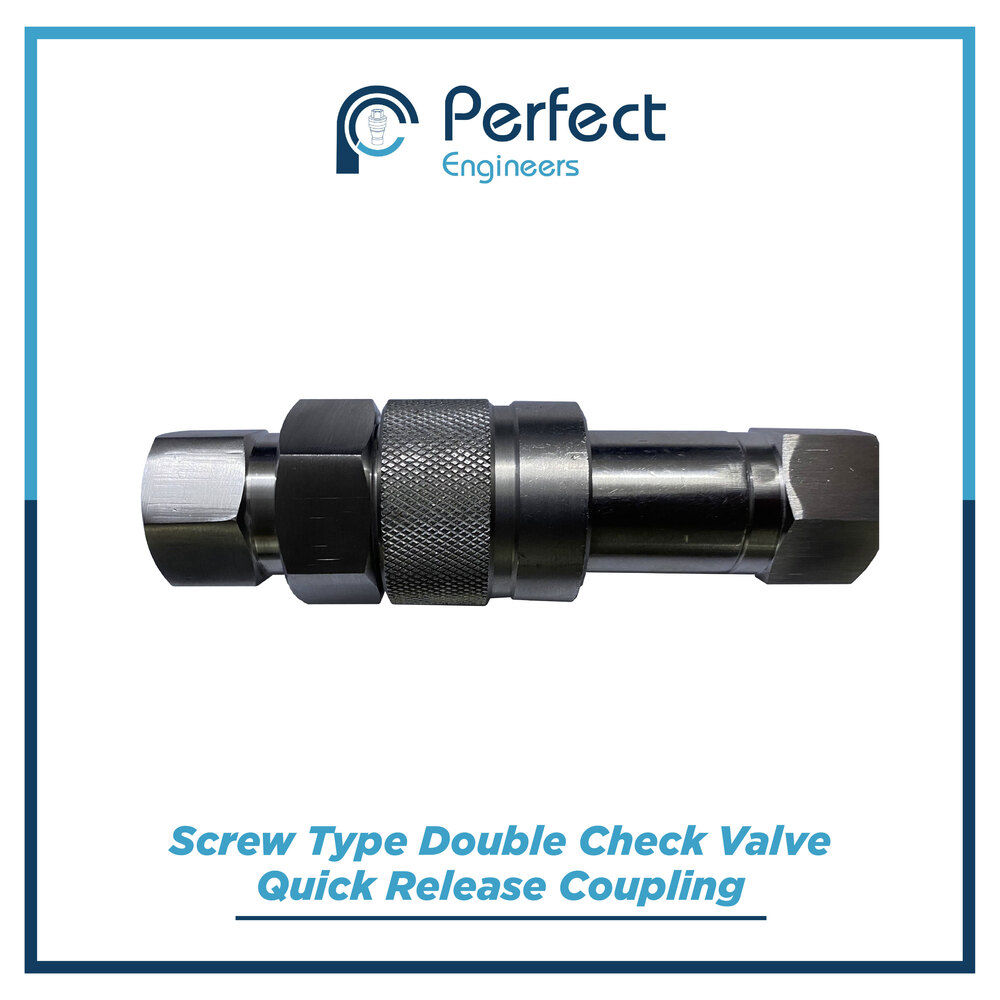

Screw Type Coupling For High Pressures

उत्पाद विवरण:

- रंग stainless steel

- साइज 0.25- 2.0

- उपयोग Industries

- प्रॉडक्ट टाइप Screw Type Coupling for High Pressures

- मटेरियल

- एप्लीकेशन Piping systems • Pneumatics

- शेप

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 50

उत्पाद की विशेषताएं

- Screw Type Coupling for High Pressures

- Piping systems • Pneumatics

- Industries

- stainless steel

- 0.25- 2.0

व्यापार सूचना

- प्रति दिन

- दिन

- standard , As per requirement.

- ISO – 9001-2015

उत्पाद वर्णन

Screw-type couplings, also known as screw-to-connect couplings, are designed for high-pressure applications requiring secure and leak-free connections. These couplings utilize a threaded connection mechanism, ensuring robust attachment capable of withstanding extreme pressures.

Key Features:

-

High-Pressure Tolerance: Designed to endure operating pressures ranging from approximately 2,320 PSI to 10,000 PSI, depending on the specific model and application requirements.

-

Secure Connection: The threaded design provides a reliable and vibration-resistant connection, minimizing the risk of accidental disconnection in high-pressure environments.

-

Material Durability: Constructed from materials such as heat-treated stainless steel, these couplings offer enhanced durability and corrosion resistance, extending their service life even in harsh conditions.

-

Versatile Applications: Suitable for various industries, including hydraulic systems, water blasting, and industrial machinery, where high-pressure fluid transfer is required.

Applications:

-

Hydraulic Systems: Facilitate the secure transfer of hydraulic fluids in machinery operating under high pressure.

-

Water Blasting Equipment: Utilized in high-pressure cleaning applications, ensuring safe and efficient operation.

-

Industrial Machinery: Provide reliable connections in equipment requiring high-pressure fluid conveyance.

Advantages:

-

Leak Prevention: The screw-to-connect mechanism ensures a tight seal, reducing the risk of fluid leaks under high pressure.

-

Ease of Maintenance: Allows for straightforward connection and disconnection, facilitating maintenance and system modifications.

-

Enhanced Safety: The secure attachment minimizes the potential for accidental disconnections, contributing to safer operation in high-pressure environments.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

Screw Type Quick Release Coupling अन्य उत्पाद

|

PERFECT ENGINEERS

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese